Fundamental Design Features of Explosion-Proof Cranes

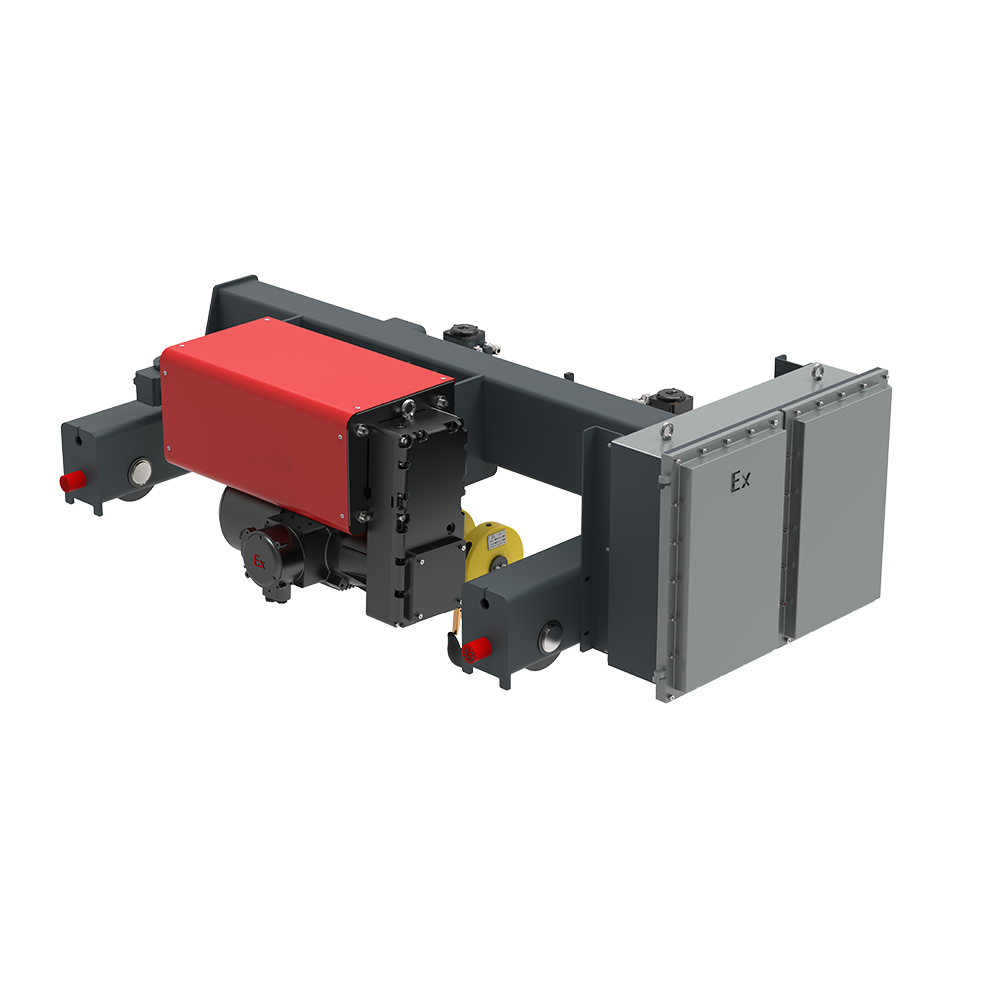

Explosion-Proof Electrical Systems and Motor Designs

In places where explosions are a real danger, explosion proof electrical systems and motors play a vital role in keeping operations running safely without setting off flammable atmospheres. These special systems get built with care to stop any kind of electrical sparking or arcing that might cause accidents. Safety matters most when dealing with areas full of vapors, fine dust particles, or combustible gases that can suddenly become dangerous. Motors marked for explosive environments are absolutely necessary equipment. They perform reliably even in tough conditions while still maintaining their safety features. Engineers design them with special construction techniques that trap any parts which could potentially generate sparks inside protective housings, making sure nothing escapes to trigger an incident.

Spark-Resistant Component Engineering

Designing parts that resist sparking is really important for keeping fire hazards down in those big cranes built for explosive environments. The materials we choose matter a lot because they help cut down on friction that can lead to dangerous sparks flying around. Most engineers go with stuff like copper alloys when making parts that might rub against each other during normal operation. We've seen what happens when companies skip this step. Remember those factory accidents where equipment just failed catastrophically? That's exactly why proper spark resistance matters so much. When manufacturers focus on these safety features upfront, their cranes work better in places where flammable materials are present, which means workers aren't constantly worried about potential disasters happening right under their noses.

Temperature Regulation Mechanisms

Keeping temperatures under control is absolutely critical when designing explosion proof cranes because it affects both safety and how well the equipment actually works. Most modern designs include things like good quality thermal insulation along with proper ventilation systems to keep everything running at safe temperatures. The real challenge comes from dealing with all the heat that builds up inside from motors and electrical parts working hard. Without proper management here, we're looking at serious problems down the road. History shows us plenty of cases where poor temperature management created dangerous situations on site. That's why getting these temperature regulation systems right isn't just important it's essential for reducing the risk of explosions and making sure cranes stay safe during operation.

Material Innovations for Hazardous Environments

Corrosion-Resistant Stainless Steel Construction

When corrosion gets into explosion proof cranes, it really messes with their structural integrity, which is why corrosion resistant materials matter so much. Especially in those dangerous work areas where cranes come into contact with all sorts of corrosive chemicals, stainless steel becomes the go to material for keeping things running safely over time. There are actually several different grades of stainless steel used in building these cranes, each one standing up better or worse against whatever environmental problems they face daily. Grade 316 stainless has become pretty popular lately because it handles corrosion better than most other options out there. Using materials that resist corrosion brings multiple benefits too many to count really. The cranes last longer obviously, need less frequent repairs, and overall create safer working conditions. When manufacturers build cranes with these resistant materials from day one, they end up lasting much longer before needing replacement parts. Operators who focus on corrosion resistant designs generally find fewer surprises when it comes to breakdowns or safety issues down the road.

Specialized Coatings for Extreme Conditions

Protecting cranes working in tough environments requires specialized coatings that act as a shield against nature's worst elements. The best coatings stand up to everything from corrosive chemicals to intense sunlight and brutal temperature swings, keeping cranes running smoothly and safely when conditions get really rough. Most modern coatings rely on stuff like epoxy or polyurethane formulas that bond tightly to metal surfaces, creating a barrier that holds up under pressure. Beyond just stopping rust, these coatings actually strengthen the crane's structure while making sure the outer surface doesn't wear down too quickly. We see these protective treatments all over the place in places like chemical plants where cranes constantly battle toxic fumes, or anywhere there are wild temperature changes throughout the day. Companies that invest in quality coatings find their cranes last much longer without breakdowns, which means fewer repairs and safer operations overall.

Compliance with Global Safety Standards

ATEX Certification for Explosive Atmospheres

ATEX certification is really important when it comes to keeping workers safe in areas where explosions could happen, especially across Europe. These ATEX rules are all about equipment and protection systems meant for places where there's a risk of explosion, so they're absolutely necessary for things like industrial cranes working in those dangerous environments. When companies follow ATEX guidelines, they're doing more than just protecting people on site – they're also covering themselves legally because regulators take this stuff seriously. Stats from the industry show that businesses which ignore ATEX requirements end up paying hefty fines and dealing with serious accidents. Take the EU for instance – they've made it clear through legislation that sticking to these standards isn't optional if we want to prevent disasters and keep employees out of harm's way.

NEC and IECEx Regulatory Alignment

The NEC and IECEx standards play a major role in crane operations worldwide, helping manage electrical risks in places where explosions could happen. The National Electrical Code works mainly across North America, whereas IECEx gets international recognition and helps bring consistency to safety measures. Looking at how they compare shows both sets of rules try to stop electrical dangers, though they apply differently depending on location and have their own technical specifics. Take Hoistcraft for instance—they've managed to follow both NEC and IECEx requirements through solid safety procedures that work well in practice. What this means for businesses is simple: sticking to these standards isn't just about avoiding fines anymore. Companies that get compliant early actually gain ground in global markets because clients trust them more when cranes operate safely and efficiently without unnecessary downtime.

Industrial Applications and Crane Variants

Rubber Tyred Gantry (RTG) Cranes in Container Handling

RTG cranes play a major role in moving containers around ports and shipping facilities. With rubber tires instead of rails, these big machines can roll freely throughout container yards, which makes them really handy for both loading ships and taking cargo off. One of the best things about RTGs is how they cut down on costs for port operators since there's no need to build expensive rail systems just to move containers around. This flexibility saves money and keeps operations running smoothly without all the extra infrastructure headaches.

RTG cranes boost operational efficiency because they allow for faster container handling, something that really matters when trying to cut down on shipping delays and get logistics flowing smoothly. Ports that switched to these cranes saw their turnaround times drop quite a bit, meaning more containers can move through in the same amount of time. Many harbors around the world have noticed this productivity jump since adopting RTG technology. These cranes work well across different yard setups thanks to how mobile they are, making them adaptable even as port configurations change over time. Some facilities report handling capacities increasing by double digits after implementation.

The integration of RTG cranes in shipping logistics continues to grow, driven by the need for efficient cargo management amidst rising global trade volumes. Statistics reveal that ports employing RTG systems experience up to a 30% increase in container handling efficiency, reflecting their critical role in modern maritime logistics.

Air Hoist Integration in Chemical Facilities

In chemical plants across the country, air hoists play a vital role when it comes to lifting operations in dangerous areas. Unlike electrical models, these pneumatic devices don't pose any spark hazards, which makes all the difference in places where flammable vapors might be present. That's why many facility managers prefer them for jobs around storage tanks or processing units. What really stands out about air hoists though is how they're built with extra safety measures baked right into the design. Most models come equipped with automatic shut off systems if something goes wrong, plus there's built in protection against overloading. These features give workers peace of mind knowing the equipment won't fail unexpectedly during critical lifting operations.

Air hoists have become a game changer for chemical plants because they lift things without all the fuss while meeting those tough safety standards everyone talks about. When these hoists get put into place, operations run smoother and workers stay safer since they can move dangerous stuff around with pinpoint accuracy. Nobody wants spills or mishaps after all. Real world experience backs this up too many factories report fewer incidents and better workflow once they switch to air hoists instead of traditional methods. The difference isn't just theoretical either most operators notice it right away.

Air hoist applications extend beyond mere safety improvements; they also contribute to increased productivity by allowing for continuous operations without compromising the safety protocols required in explosive environments. Their effectiveness in handling complex lifting tasks makes them indispensable equipment in modern chemical plant operations.

Travel Lift Systems for Offshore Operations

Travel lifts have changed how work gets done at sea thanks to their strong and reliable lifting capabilities that are essential for maintaining ships and building new ones. Most of these portable cranes come with big overhead frames and rubber wheels, allowing them to move around freely and place boats exactly where they need to be on dry ground. The ability to do this makes all sorts of repairs much easier while also cutting down on transportation costs since there's no requirement for expensive fixed facilities or docks when moving smaller vessels between locations.

Travel lifts come with several important safety and operational features worth noting. They typically have remote controls for operation, can position loads very accurately, and are equipped with sophisticated load monitoring tech. All these features make sure boats and ships get handled safely, especially out at sea where weather conditions can change rapidly from one moment to the next. When looking at them side by side with old school crane setups, travel lifts just plain work better most of the time. They give operators more freedom on the job site and keep things moving even when unexpected issues pop up during loading or unloading operations.

Studies on travel lift systems show they work really well in offshore environments. According to industry reports, these systems cut down dry docking time by around 40% in many cases, which makes a big difference when vessels need maintenance. Operators have noticed this time saving firsthand, especially during peak seasons when every hour counts. We're seeing more adoption across the sector too. Companies want dependable ways to move equipment and materials quickly, particularly as weather patterns become harder to predict and regulations get stricter about vessel safety standards.