הכרת מכשורים חשמליים אטומים לאש ותפקידם בסביבות מסוכנות

הגדרה ואובייקטיבי הבטחה עיקריים של מערכת הרמת סרוו בסביבות מסוכנות

מערכות הרמה סרוו הנמצאות בסביבות מסוכנות הן בסך הכל הרמות ממונעות שנועדו לעבוד בבטחה במקום שבו יש סיכון מغازים דלקניים, אדים או אבק שעלולים להבער. המטרות העיקריות בעת תכנון מערכות אלו כוללות הסרת כל ניצוץ פוטנציאלי, ודא כי הן ממשיכות לפעול גם בתנאים קיצוניים, והצלחת כל תקני הבטחה בינלאומיים לאזורים מסוכנים. לדוגמה ניתן לציין מפעלי פטרוכימיה, שבהם ריכוזי מתאן לעיתים עולים על 5% כפי שצוין בהנחיות NFPA 70. לכן, הרמותทน-אש נוצרות מחומרים שלא ייצרו ניצוץ, ומכילים רכיבים חסיני אבק ו לחות. סקירת ביטחון תעשייתית עדכנית משנת 2023 חשפה גם משהו די מרשים - מקומות עבודה ששימושו בציוד מוסמך למניעת התפוצצויות הצליחו להפחית באופן דרמטי את תחלות הדלקת, בכ-92% בהשוואה לציוד רגיל. לא מפתיע companies why companies invest extra in these specialized systems despite the higher costs upfront.

איך שרשרות איטום מונעות התלקחות באטמוספירות דליקות

שרשראות חשמליות שפותחו לסביבות איטום מצוידות בכמה אמצעי הגנה מובנים המונעים מהאוויר הפקקתי להבעיר. המרכיבים המרכזיים? גוף שמחזיר ניצוץ פנימה, מעגלים שמתוכננו כך שלא ייצרו מספיק חשמל שיוכל לגרום להתפוצץ, ובנוסף מנגנוני הגנה תרמית שפועלים לפני שהטמפרטורה עולתה מדי. יצרנים מציידים את היחידות בבדיקות מקיפות כדי להבטיח עמידה בדרישות ATEX ו-IECEx, אשר מציינות אזורים שונים על פי הרגע שבו גזים מתפוצצים עשויים להיות נוכחים. מחקרים עדכניים משנת 2023 הראו גם משהו די מרשיע: שרשרות שצוידו באטימה כפולה הפחיתו את הסיכוי שהגזים יגרמו לשרפות ב-84% במקשה במתכנתות שבהן סיכונים כאלה נפוצים.

ההבדלים המרכזיים בין שרשרות רגילות לבין שרשרות איטום חשמליות (Ex)

| תכונה | שרשראות רגילות | שרשראות איטום |

|---|---|---|

| עיצוב הקליפה | מאוורר או מסגרת פתוחה | מונחמר, מחוזק |

| סטנדרטים של חומר | מתכות למטרות כלליות | سبائك מתכות לא יוצרות ניצוץ (למשל ניקל-נחושת) |

| הסמכות | CE, ISO | ATEX, IECEx, NEC 500/505 |

| מגבלות תפעול | טמפרטורת הסביבה בלבד | במתכונת של -20°C עד +60°C עם חומרים נדיפים |

בעוד שרוכנות סטנדרטיות מדגישות יעילות ביחס למחיר וגמישות, מערכות עם דירוג Ex ממקדות את המורכבות האנושית והפיזית של אמצעי ביטחון כפולים. לדוגמה, מודלים בעלי הגנה נגד פיצוץ כוללים חיישני טמפרטורה שסוגרים אוטומטית את הפעולה אם הטמפרטורה הפנימית עולה על 40°C - הגנה חיונית שאינה קיימת בציוד קונבנציונלי.

סיווגי אזורי סיכון ותקני תאמה (אזור 0, 1, 2)

סקירת קטגוריות של אזורי סיכון: אזור 0, אזור 1 ואזור 2 לאטמוספרות נפוצות

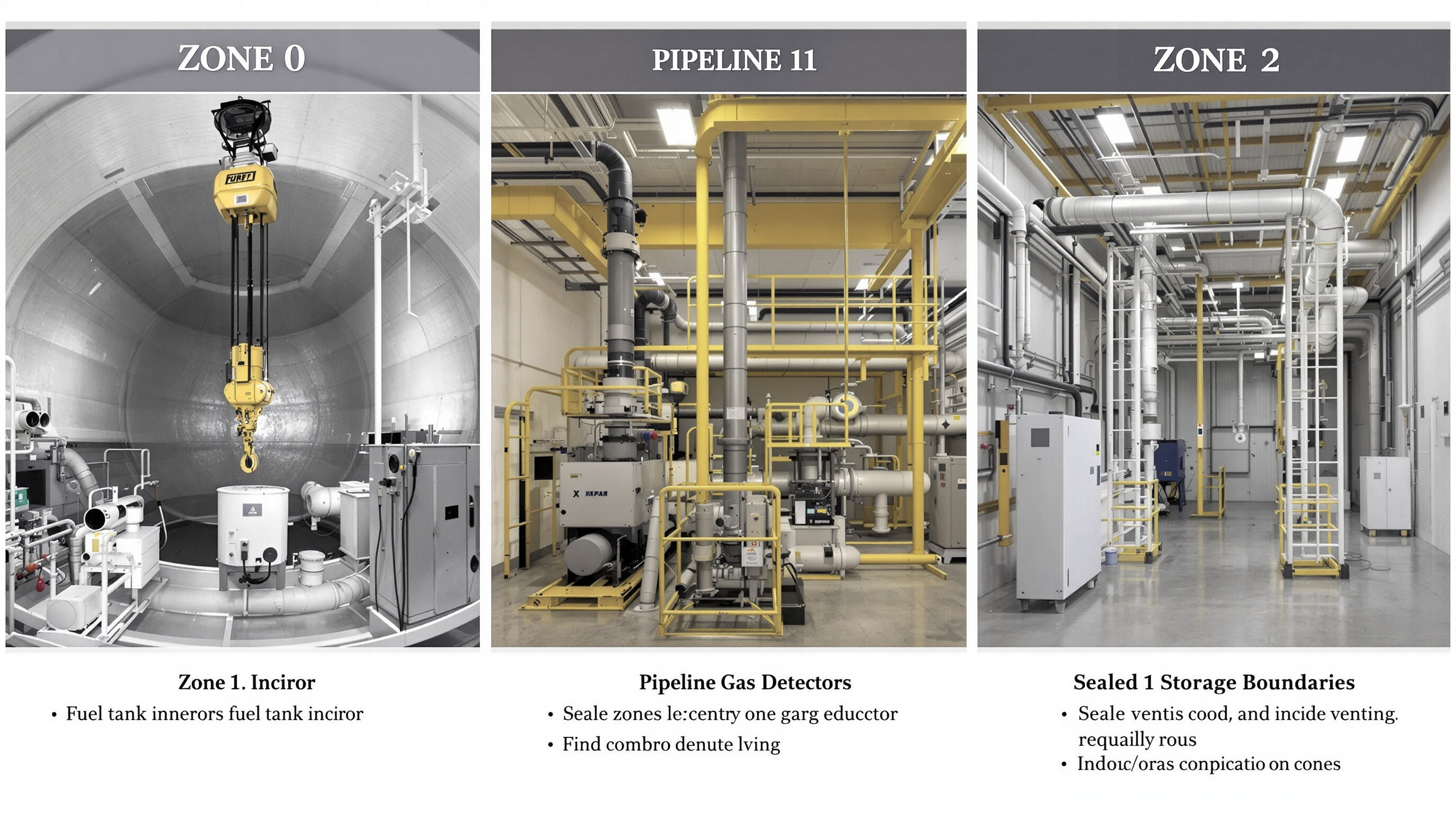

סביבות מסוכנות מסווגות ל איזור 0 , איזור 1 , ו אזור 2 בהתאם לתדירות ולמשך הזמן של נוכחות גז או אבק דליק. סיווגים אלו קובעים את רמת הבטחה הנדרשת למערכות הרמה סרווו:

| אזור | רמת הסיכון | נוכחות האטמוספרה | סביבות דוגמה |

|---|---|---|---|

| 0 | גבוה ביותר | רציפה (>1000 שעות/לשנה) | מכלות דלק, כלי תגובה |

| 1 | בינוני | Occasioneel (10–1000 uur/jaar) | קווים, תחנות משאבה |

| 2 | נמוכה יותר | נדירה (<10 שעות/לשנה) | אזורי אחסון, פתחי אוורור |

סביבות באיזור 0 מחייבים שרשלים בעלי אישור Ex ia—דרגת הבטחה הגבוהה ביותר—שמבטיחים פעולה בטוחה תחת חשיפה מתמדת לסביבות מתפוצצות.

התאמת מפרט השרשלי הידראוליים לאזורים מסוכנים

לציוד הפועל באזורים של איזור 0, מערכות הרימה servo מזדקקות למנועים חסומים לחלוטין וכן חיישנים תרמיים גיבוי כדי למנוע היווצרות ניצוץ. שרשלים המשמשים באזורים של איזור 1 חייבים לעמוד בערך בעשר התפוצצויות לפני כשל, בעוד שמכונות באיזור 2 מזדקקות לפחות לרכיבים חשמליים חסומים לפי תקן IP65. רבים מייצרנים מובילים משתמשים כיום בתוכנת תחזוקה חכמה שמתאימה את משך חיי השרשלים לסוגים השונים של סיכונים בהם הם פועלים באזורים השונים. גישה זו מצמצמת את סכנת הדלקת בכ-83 אחוזים בעבודה סמוך לגזים דלקתיים, כך לפי ממצאים עדכניים שפורסמו ב-Industrial Safety Journal בשנת 2023.

תאימות תורנית: סטנדרטים של ATEX, IECEx ו-NFPA לפי אזורים

סטנדרטים גלובליים מנהיגים את triểnת ציוד עמיד בפני פיצוצים:

| סטנדרטי | טווחוֹר | התאמת אזורים מרכזית |

|---|---|---|

| ATEX | EU | אזורים 0-2 (הנחייה 2014/34/EU) |

| IECEx | בינלאומי | אזורים 0-2 (Ex ia/ib/ic) |

| NFPA 70 | צפון אמריקה | Class I/II חלוקות 1-2 |

אישורי ATEX ו-IECEx מחייבים אימות על ידי צד שלישי של רכיבי מערכת הרמה סרוו במחזורים אופרטיביים של 500+ תחת תנאים של אזורים 0-2 מדומים. עיצובים المتوافق עם NFPA מדגישים הגנה כפולה מפני תקלות בארקות כדי לעמוד בדרישות NECArticle 500 למיקומים מסוכנים.

טכנולוגיות ביטחון מרכזיות: מנועים עמידים בפני פיצוצים, אטימה מלאה וניהול טמפרטורה

טכנולוגיה של מנועים חסיני פיצוץ: הכלה בטוחה של פיצוצים פנימיים

מנועים חסיני פיצוץ מצופים בקופסאות מיוחדות, שעשויות מפליז אלומיניום או ברזל גמיש, שיכולות להכיל כל פיצוץ פנימי שיתכן יתרחש. מנועים רגילים פשוט מפלטים ניצוצות וחום כאשר יש בעיה חשמלית, אבל אלו שומרים על הכל סגור פנימה. כאשר הם עוברים מבחנים לפי תקני IECEx ו- ATEX, הם מצליחים להתמודד עם עליות לחץ של כ-15 פאונד לאינץ' מרובע מבלי לשבור או להתפורר. היתרונות? לפי דוחי ביטחון עדכניים משנת 2023 של UL, מנועים אלו מקטינים את הסיכן לפיצוץ ב-98 אחוז לעומת ציוד לא מאושר.

שיטות חותם הרמטיות כדי להפריד בין מערכות חשמל ואבק וغازים פיצוצניים

מערכת החותם בעלת השלוש שכבות, עם דירוג IP66/67, עוצרת באופן בסיסי כל חומר דליק מלהיכנס, בין אם מדובר בחלקיקי אבק או באדים. מתקנים העוסקים בחומרים מסוכנים כמו פרופאן או אבק פחם זקוקים לתכונות אלו, מכיוון שציוד רגיל פשוט אינו מספק. מעברי הכבלים נעלמו, והוחלפו בארגזות החיבור המותכות שמעצירות ניצוץ מיידית. על פי דוח של OSHA שפורסם בשנה שעברה, חברות שהקפידו לוודא שהמערכות שלהן חסומות כראוי, חווו תופעה מפתיעה. מספר התאונות האקספלוסיביות ירד ב-90% למשך חמש שנים. שיפור בביטחון ברמה זו הופך את כל ההשקעה למשהו שווה-ערך עבור תפעול תעשייתי שמעוניין בהפחתת סיכונים במקום העבודה.

התפקיד של הגנה תרמלית במניעת הצתה עצמית של חומרים נדיפים

חיישנים תרמיים מתקדמים שומרים על מעגלי המנוע כל הזמן, ומכבים את הכוח כל פעם שהטמפרטורה עולה על 155 מעלות צלזיוס. זה די חכם, שכן משאיר שולי ביטחון נאים מתחת למה שעשוי להצית הידרוקרבונים רבים. בתי המנוע כוללים כיום לעיתים קרובות חומרים מיוחדים בעלי יכולת שינוי פאזה שסופגים את החום העודף, כך שהמשטחים נשארים קרים גם כשעומסים את המנועים מעבר לגבולות הרגילות שלהם עד 150%. הערך האמיתי כאן בא לידי ביטוי כשמביטים בסטטיסטיקות תאונות של NPFA מהשנה שעברה, שמראות שבעיות תרמיות תרמו לכמעט רבע מכל פיצוצות התעשייתיים. לכן, גם שאולי שיפורים אלו נראים זניחים, הם תורמים להרבה לשיפור הבטחה במפעלים ברחבי המדינה.

דרגות הגנה של IP ו-NEMA להגנה סביבתית במכשורים אטומים לפיצוץ

| תקן הגנה | סיכון מופחת | דוגמה ליישום |

|---|---|---|

| IP66 | כיבוי תחת לחץ של מים | אזורי שטיפה ימיים |

| NEMA 4X | קורוזיה עקב אדי חומצה | מפעלי עיבוד כימיקלים |

| IP69K | ניקוי קיטור | אזורי אבק דשנים בדרגת מזון |

מכשורים המשלבים הגנה על שטיפה בדרגת IP68 עם דירוג התפוצצות NEMA 7 מציעים ביטחון אופטימלי בסביבות אזור 1 עם נוכחות רציפה של גזים דליקים.

מערכות ביטחון תפעוליות: הגנה מפני העומס, מפסקים גבשורים, ופונקציות של שלט רחוק

גבשורים אוטומטיים ומדידת עומס במערכות הרמה הסרוו

מערכות הרמה הסרוו של ימינו מצוידות במקשה גבשורים אוטומטית ובעקיבה בזמן אמת של העומס שמסייעות לשמור על גבולות ביטחוניים. כאשר הוווים מתקרבים מדי לנקודות מסוכנות, מופעלים הגבשורים ומפסיקים את התנועה מיידית. במקביל, חיישני עומס מיוחדים עוקבים כל הזמן אחר התפלגות המשקל במערכת. גם הנתונים תומכים בכך. דוח אחרון ממומחי הבטיחות של מנופים מראה שכשמקומות משתמשים בשדרוגים הטכנולוגיים האלה, הם מפחיתים ב-42 בערך את מספר תאונות העומס השנתי באזורים מסוכנים. זה קורה בגלל שהמערכת מעדכנת אוטומטית את הגדרות ההרמה כשהיא מרגישה מה בדיוק נישא באמת.

מנחות ביטחון למניעת עומסי מכאניקה וחשמל

מכשורים בעלי עמידות לפיצוץ משתמשים במערכות בלימה כפולות ובמכסי חום כדי לנהל סיכונים של עומס. בלמי אלקטרו-מגנטיים כפולים מופעלים בתוך 0.3 שניות במקרי תקלה חשמלית, וחיישני טמפרטורה מושבתים את המנועים לפני שמגיעה לסדרת ההצתה האוטומטית של חומרים דליקים—מאמתים לפי ISO 13849. הגנה מרובת שכבות זו מבטיחה עמידה בדרישות תקן אזור 1 ואזור 2.

יתרונות הפעלה מרחוק בהפחתת חשיפה של עובדים לאזורים מסוכנים

שלטים תקשורת חוטיים ובקרות ממשקיות מותאמות ל-IoT מאפשרים לאופרטורים לנהל את הרומ.lifts ממרחק של עד 150 מטרים. תכונה זו היא חיונית במפעלי פטרוכימיה ועל מתקנים באוקיינוס, שם הפעלה מרחוק מקטינה את חשיפת העובדים לסביבות פיצוציות ב-78% בהשוואה למערכות ידניות (Ponemon 2023).

שילוב של מערכות עצירה דחופה ותיכנות בזמן אמת

tờם תליות עם הגנה מתקדמת נגד פיצוצים, מערכות ניתוק לשעת חירום עם זמני תגובה של פחות מ-5 מילישניות ומערכות אבחון שפוקדות על יותר מ-10 פרמטרי פעולה. מעקב בזמן אמת אחר תקלות זיהה סימנים מוקדמים של בלאי Lager או ירידה באיכות האיזולציה, מה שמאפשר תחזוקה מקדימה ופחתת את זמני השבתה הלא מתוכננים ב-35% בסביבות סיכון גבוה.

יישומים תעשייתיים ושיטות עבודה מומלצות לבחירת מערכות הרמה סרוו

tờם תליות חשמליות עם הגנה against פיצוצים בפלטפורמות ימיות, מתקני רתיחה ומכרות פטרוכימיים

מערכות הרמה הסרווואיות המוגנות against פיצוץ משחקות תפקיד קריטי בפלטפורמות נפט וברפינריות שבהן גזים ו אדים דלקתיים יוצרים סיכוני אש מתמשכים. הרכבלות המותאמות פועלות באופן מהימן באזורים מסוג 1, ומרימות הכול - ממכשורים כבדים ועד חלקי חיבור עדינים - מבלי ליצור ניצוצות שעלולים להפעיל פיצוצים מסוכנים. ההבדל מרגיש בפעילות - פחות הפסקים לא צפויים משמעותם ייצוריות טובה יותר באופן כללי. לפי ממצאים שפורסמו בדוח הבטחה באופשיור 2023, בFacilities המשתמשות בציוד מותאם ומאושר against פיצוץ נעלמו כמעט 4 מתוך 10 מקרי תחזוקה לא מתוכננים, בהשוואה למערכות ישנות שאינן מאושרות במנחות עיבוד גז דומות.

תהליך כימי והעשרת מינרלים: טיפול בחומרים דליקים ואבק נפץ

תפעול מכרות ותהליכי כימיה תולים במערכות הרמה סרוו כדי למנוע תהליכים מסוכנים הנובעים מפarks או תופעות חום מוגזם. המערכות משתמשות בשרשורים הרמטיים כדי להרחיק רכיבים חשמליים מאבקים דלקתיים כמו חלקיקי פחם או אבקת גופרית. כאשר הטמפרטורה עולתה על הרצוי, חיישני חום מופעלים ומכבים את כל המערכת אוטומטית לפני שהמצב יתפסול. עבור חברות הפועלות בתוך האיחוד האירופי, קבלת תעודת ATEX לציוד ההרמה אינו רק מומלץ - אלא חובה כאשר יש מגע עם חומרים נפוציים. תהליך זה עוקב אחרי סטנדרטים החמורים של הנחיית 2014/34/EU, דבר שכל מנהל מתקן מודע אליו והוא נאלץ לעקוב אחריו כדי לשמור על דרישה חוקית ולמנוע תאונות חמורות.

אסטרטגיה: בחירת סוג הרמה הנכון בהתבסס על סיכונים ספציפיים לתעשייה

שיקולים מרכזיים לבחירה מיטבית:

- සיווג סיכון : התאמה של תעודות הרמה (IECEx, NFPA 70) לדרישות אזורי 0/1/2

- הגנת הסביבה : יש להעדיף דירוג IP66 או NEMA 4X להתנגדות לאבק ול לחות

- תנודות עומס : ודא שהמערכות מסוגלות לעמוד בעומסי מכה בעבודות כרייה או שינויים פתאומיים בתפעול ימי

- פעולה מרוחקת : שליטה אלחוטית מפחיתה את החשיפה של עובדים באזורים מסוכנים

על ידי התאמה של הגורמים הללו לצרכים התפעוליים, תשומות יכולות לשמור על תפוקה תוך הפחתת סיכונים הקשורים לעמידה בדרישות ב סביבות דליקות.

שאלות נפוצות

מהו שרשרת חשמל נגד פיצוץ?

שרשרת חשמל נגד פיצוץ היא ציוד הרמה ממונע שתוכנן לפעול בבטחה בסביבות בהן קיימות גזים דליקים, אדים או אבק, במטרה למנוע הצתה

איך שרשראות נגד פיצוץ מונעות הצתה?

הן משתמשות בקופסאות כבויות-להבה, מעגלים הנדסיים לייצור אנרגיה נמוך, ו הגנה תרמלית כדי ללכוד ניצוצות, לשלוט בטמפרטורה, ולמנוע הצתות

אילו תעודות היגיון נדרשות לשרשראות חשמל נגד פיצוץ?

אישורים כמו ATEX, IECEx ו-NEC Compliance הם אס Rim Lahovrim liyeshorat bakara be zones sakhunas lehakim et habitachon.

מהן מיונai hatfusot baad hazarot?

הן ממוינות ל-Zone 0, Zone 1 ו-Zone 2, על פי שכיחות ההימצאות של חומרים דלקניים, מה שמגדיר את רמת הביטחון הנדרשת לציוד.

למה יש חשיבות למכשורים נגיני התפוצצות בתעשייה כמו בתפוצות נפט?

המכשורים הללו מונעים ניצוץ וסכנות אש נגזרות, ומבטיחים הרמת ציוד בבטחה בסביבות המועדות לגזים או אדים דלקניים.

תוכן העניינים

- הכרת מכשורים חשמליים אטומים לאש ותפקידם בסביבות מסוכנות

- סיווגי אזורי סיכון ותקני תאמה (אזור 0, 1, 2)

- טכנולוגיות ביטחון מרכזיות: מנועים עמידים בפני פיצוצים, אטימה מלאה וניהול טמפרטורה

- מערכות ביטחון תפעוליות: הגנה מפני העומס, מפסקים גבשורים, ופונקציות של שלט רחוק

- יישומים תעשייתיים ושיטות עבודה מומלצות לבחירת מערכות הרמה סרוו

- שאלות נפוצות