ما هي سعة تحمل الرافعة ذات العارضة المفردة ولماذا تهم

التعريف والمفهوم الأساسي لقدرة التحميل

بشكل أساسي، تعني قدرة تحمل الوزن للرافعات ذات العارضة الواحدة كم الوزن الذي يمكن نقله بأمان دون كسر أي شيء مهم. ما الذي يحدد هذا الرقم؟ في الحقيقة، يعتمد ذلك على نوع المواد المستخدمة في صنع العارضة، وكيف تم تجهيز عربة الرفع، وعلى تصميم العوارض ككل. عادةً ما يضع المهندسون هامشًا إضافيًا للأخطاء عند حساب هذه القدرات، حوالي 20 إلى 25 بالمائة أكثر من القيمة المعلنة رسميًا. خذ على سبيل المثال رافعة يفترض أنها تستطيع تحمل 15 طنًا، فعند الاختبار يجب أن تكون قادرة على تحمل ما يصل إلى 18 طنًا قبل منحها الضوء الأخضر. يضمن هذا الاختبار أن الرافعة لن تنثنى تحت الضغط عندما تزداد الأمور تعقيدًا في الموقع مع التأثيرات غير المتوقعة المختلفة.

التطبيقات الصناعية والصلة في بيئات الأعمال بين الشركات (B2B)

تعمل الرافعات ذات العارضة الواحدة بشكل جيد حقًا في مرافق التصنيع والمستودعات عند التعامل مع أحمال أقل من 20 طنًا، خاصة عندما تكون المساحة محدودة أو الميزانية ضيقة. إن التصميم الأبسط يقلل بشكل كبير من تكاليف التركيب مقارنةً بالرافعات ذات العارضتين، ولذلك يتجه العديد من المصانع إلى هذا النوع من الرافعات لأعمال مثل تجميع مكونات السيارات، أو إنتاج السلع الإلكترونية، أو نقل المواد في منشآت صغيرة. في الغالب، تتجه قرارات الشراء بين الشركات إلى هذه النماذج في العمليات التي تتطلب رفع أشياء خفيفة بانتظام (عادةً أقل من 15 طنًا) على مسافات تقل عن 80 قدمًا. وفي مثل هذه الحالات، يكون التركيز على تحقيق قيمة جيدة مقابل المال أكثر من الحاجة إلى قوة رفع هائلة.

العوامل الرئيسية التي تحدد قدرة تحمل الحمولة في الرافعات ذات العارضة الواحدة

تصميم العارضة وقوة المواد المستخدمة في صنعها

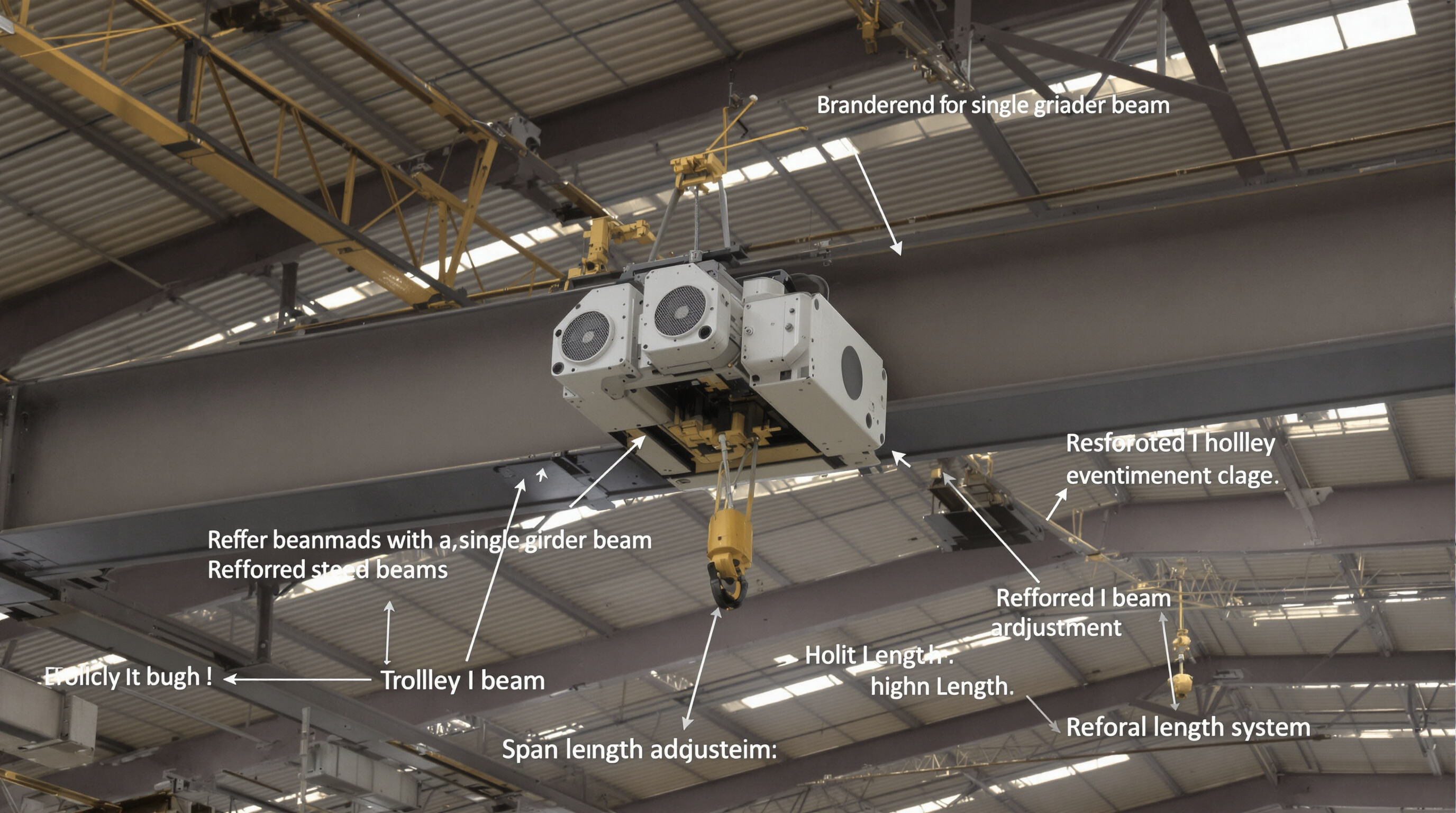

عند مناقشة كمية الوزن الذي يمكن للعارضة تحمله، فإن طريقة بناء العارضة والمواد المستخدمة في صناعتها تلعب دورًا كبيرًا. يلتزم معظم الصناعيين باستخدام الفولاذ عالي القوة والذي يمتلك حد خضوع لا يقل عن 250 ميغاباسكال، لأن هذا النوع يوفر متانة جيدة دون أن يكون ثقيلًا جدًا. كما تلعب شكلية المقطع العرضي دورًا كبيرًا أيضًا، وخصوصًا العلاقة بين الأبعاد الخاصة بالارتفاع والعرض. على سبيل المثال، يمكن للعارضات المدعمة على شكل حرف I عادة تحمل ما يقارب 15 إلى 20 بالمئة إجهادًا إضافيًا مقارنةً بتصاميم اللوحات المسطحة عندما تتعرض للأحمال نفسها. هذا ما يجعلها تدوم لفترة أطول وتؤدي بشكل أفضل في المشاريع الإنشائية الفعلية حيث تكون سلامة البنية مهمة.

طول الفتحة وترتيب العارضة في الجسر

بشكل عام، كلما زاد طول الجمالون (Span) كلما قلّت قدرته على تحمل الأوزان. على سبيل المثال، يمكن للكباري ذات الجمالونات التي يبلغ طولها حوالي 20 مترًا أن تحمل ما يقارب 25 بالمئة أقل من تلك التي يبلغ طول جمالوناتها 10 أمتار، وذلك لأن الجمالونات الأطول تكون أكثر عرضة للانحناء تحت الضغط. وعند تصميم هذه الهياكل، يضيف المهندسون عادةً عمقًا إضافيًا للعتبات (Girders) مع زيادة طول الجمالون، وبنسبة تقارب 1.5 إلى 2 سنتيمتر لكل متر إضافي يجب تغطيته. ويساعد هذا التعديل في الحفاظ على القوة على مسافات أطول. كما يجب أن تظل عوارض التشغيل (Runway beams) محاذاة ضمن تفاوت ضيق للغاية، لا يزيد عن 3 ملليمترات بينها. وتحافظ المحاذاة الصحيحة على توزيع متساوٍ للأوزان عبر الهيكل بأكمله، مما يمنع ظهور نقاط ضعيفة ويضمن استقرار النظام بالكامل تحت مختلف الأحمال والظروف.

ارتفاع الرفع، نوع العربة، وتكامل الرافعة

عندما تزيد ارتفاعات المكابس عن 15 مترًا، يجب أن تكون سماكة س rails العجلات حوالي 10 إلى 12 بالمائة أكثر فقط لتحمل قوة التأرجح هذه. وبالحديث عن الموثوقية، فإن المكابس بدون تروس تتميز حقًا في هذا المجال. فهي تظل تعمل بنسبة 98.4 بالمائة من الوقت في الأنظمة ذات العارضة الواحدة، في حين تصل المكابس التقليدية ذات التروس إلى حوالي 94.7 بالمائة، وفقًا للتقارير الحديثة الخاصة بمناولة المواد لعام 2022. ولا تنسَ أيضًا قاعدة عجلات العربة. يجب أن تكون على الأقل 30 بالمائة من عرض فتحة العارضة. وإلا فإن هناك مشكلة في الاستقرار الجانبي أثناء الحركة، وهو ما لا يريده أحد لأنه يجعل العمليات غير آمنة وبطيئة بشكل محبب.

عوامل الأمان والحمولة القصوى لمنع الإفراط في التحميل

وفقًا لمواصفة CMAA 74، يجب أن تكون هناك هامش أمان يبلغ أربع مرات الحمل العامل للرافعات ذات العارضة الواحدة. إذن إذا كنا نتحدث عن رافعة بسعة 5 أطنان، فهي في الواقع تحتاج إلى تحمل 20 طنًا قبل أن تظهر عليها أي علامات تلف. بالنسبة لمؤشرات حد الحمل التي تأتي بدقة تبلغ حوالي زائد أو ناقص 2٪، فإن الصيانة الدورية مهمة جدًا. عادةً ما تشهد المنشآت التي تتبع هذه القاعدة مشاكل أقل في زيادة الحمل. تشير بعض البيانات من عمليات تفتيش OSHA بين عامي 2021 و2023 إلى أن هذه الفحوصات الربع السنوية تقلل من حوادث الإفراط في التحميل بنسبة تصل إلى ثلاثة أرباع. عند تشغيل هذه الآلات، يعرف العمال المتمرسين أنهم يجب أن يتركوا سعة إضافية تبلغ حوالي 12٪ احتياطيًا، وذلك لأن الظروف الواقعية ليست دائمًا مثالية. تحدث أشياء مثل التسارع المفاجئ أو التوقفات المفاجئة التي يمكن أن تؤدي إلى خلل في الحسابات.

الرافعات ذات العارضة الواحدة مقابل الرافعات ذات العارضتين: سعة التحميل والمقايضات الهيكلية

الاختلافات التصميمية المؤثرة على سعة التحميل والاستقرار

تُعَدُّ الرافعات ذات العارضة الواحدة تعتمد على عارضة رئيسية واحدة فقط لحمل نظام العربة والرفع، مما يجعل هذه النماذج ميسرة إلى حد كبير عند التعامل مع المواد ذات الوزن الخفيف عادةً تحت 20 طنًا. أما الرافعات ذات العارضتين فتعمل بشكل مختلف حيث تحتوي على عارضتين متوازيتين، مما ينتج عن إطار أكثر متانة يمكنه التعامل مع الأوزان الثقيلة التي تفوق هذا الحد. وهي مُناسبة بشكل خاص للمهام الصناعية الصعبة مثل العمل مع مكونات الفولاذ أو أجزاء الضغط للسيارات حيث تكون القوة هي العامل الأهم. ما يميز أنظمة العارضتين هو قدرتها على التعامل مع الأحمال الأكبر دون التأثير على الاستقرار، كما أنها توفر تحركًا أفضل عبر المساحات الأكبر مقارنةً بالإصدارات ذات العارضة الواحدة.

- مقاومة الالتواء أعلى بنسبة 40% ، وتقلل من التأرجح أثناء الحركات الجانبية (تحليل أنظمة الرفع الصناعية 2024)

- ارتفاع الخطاف أعلى بنسبة 18–22% نظرًا لوضعية الرافعة في منتصف العارضة

- ممرات متكاملة وأنظمة مضادة للانحراف لضمان صيانة وتشغيل أكثر أمانًا

وبحسب تقرير كفاءة مناولة المواد، فإن التكوينات ذات العارضتين تتميز بعمر إجهاد أطول بنسبة 30٪ في البيئات ذات الدورة العالية مقارنةً بالنظام ذي العارضة الواحدة.

متى يجب اختيار رافعة ذات عارضتين لطلبات الأحمال الأعلى

يُوصى باستخدام الرافعات ذات العارضتين عندما تشمل العمليات ما يلي:

- أحمال تزيد عن 20 طنًا : تُظهر بيانات الصناعة أن 63٪ من مرافق ختم السيارات تستخدم عارضتين في تركيبات خطوط الضغط.

- فتحات تزيد عن 30 مترًا : يدعم التصميم ذو العارضتين الوصول إلى مسافات أطول دون الحاجة إلى أعمدة في منتصف الفتحة.

- استخدام يومي عالي (>75%) : تعزز نقاط اللحام المعززة والتوزيع المحسن للإجهاد المتانة في بيئات الاستخدام المستمر.

تتطلب مواصفة CMAA 74 وجود عامل أمان في التصميم بنسبة 1.5:1 للرافعات ذات العارضة المزدوجة في تصنيع المكونات النووية، وهو ما يقل بنسبة 22% عن متطلبات العارضة الفردية، مما يبرز دورها في التطبيقات الحيوية. وعلى الرغم من ارتفاع تكلفتها الأولية بنسبة 18-25%، فإن التعويض الهيكلي في العوارض المزدوجة يبرر الاستثمار في العمليات الدقيقة والكثيفة السعة.

الامتثال والمعايير الخاصة بسعة التحميل في تصميم الرافعات العلوية

مواصفة CMAA 74 والمحددات القياسية للتصميم في الصناعة

تحدد رابطة مصنعي الرافعات في أمريكا (CMAA) إرشادات السلامة المهمة من خلال وثيقة المواصفة 74 الخاصة بها. وتشمل هذه الإرشادات أشياء مثل الوزن الذي يمكن للرافعات تحمله، وأنواع التآكل التي يجب أن تتحملها على المدى الطويل، وحدود الإجهاد التي يمكن أن تتعرض لها المواد. تساعد هذه المواصفة في الحفاظ على قوة الرافعات ذات العارضة الواحدة حتى عند استخدامها في أماكن صعبة مثل المصانع والمستودعات يومًا بعد يوم. خذ على سبيل المثال مصانع تجميع السيارات حيث يتم اختبار الرافعات باستمرار. وبحسب مواصفات CMAA 74، يجب أن تكون هذه الآلات قادرة على تحمل كل هذا العمل المتكرر دون فقدان قوتها أو موثوقيتها. كما أظهرت دراسة صناعية حديثة لعام 2023 نتائج مثيرة للاهتمام أيضًا. فالمصانع التي تتبع معايير CMAA سجلت انخفاضًا بنسبة 40 بالمائة في عدد الأعطال مقارنة بتلك التي لا تلتزم بهذه المتطلبات. وهذا أمر منطقي حقًا، حيث أن الصيانة المناسبة والالتزام بالمواصفات يجعل كل شيء يعمل بسلاسة على المدى الطويل.

الشهادة والاختبار والتحقق من الأداء

يشمل الامتثال التحقق الصارم من العمليات. البدء اختبار الحمل يتطلب من الأوناش رفع 125% من قدرتها المقدرة - وهو متطلب تفرضه OSHA 1910.179 و ASME B30.2. فعلى سبيل المثال، يجب أن تتمكن ونش العارضة الواحدة بسعة 10 أطنان من التعامل بنجاح مع 12.5 طن دون حدوث تشوه هيكلي. يقوم المفتشون من جهات خارجية بتقييم:

- أداء فرامل الرفع تحت الأحمال القصوى

- انحناء العارضة (محدود إلى أقل من 1/1000 من طول الجهة)

- استقرار عربة الونش أثناء التسارع والتباطؤ

توصي مواصفات CMAA رقم 78 بإعادة الشهادة كل أربع سنوات، مع فحوصات موثقة لكابلات الفولاذ والتروس وعجلات العربة. تواجه المنشآت التي تتجاهل هذه البروتوكولات معدلات مخالفة من OSHA تزيد ثلاث مرات، وفقًا لبيانات السلامة الصناعية لعام 2022.

التطبيقات الواقعية وتحسين استخدام سعة ونش العارضة الواحدة

دراسة حالة: تحقيق مكاسب في الكفاءة بخط تجميع السيارات

وفقًا لتقرير Automotive Manufacturing Quarterly الصادر العام الماضي، شهدت مصنع سيارات في وسط الولايات الأمريكية زيادة في حجم الإنتاج بنسبة تقارب 22% بعد استخدام رافعات علوية أحادية العارضة بسعة 5 طن لنقل كتل المحركات عبر أرضية المصنع. ما يميز هذه الرافعات هو قدرتها على نقل القطع بين محطات التشغيل بدقة تقارب المكان المطلوب، حيث لا تتجاوز نسبة الخطأ 2 ملمتر في معظم الأحيان، وهو ما يناسب المهام التي تتطلب تحملًا جيدًا للأوزان مع تفاوتات ضيقة. من بين المزايا أيضًا ما تم توفيره من تكاليف التركيب مقارنة بالأنظمة التقليدية ذات العارضة المزدوجة، إذ بلغت نسبة التوفير حوالي 28%. وقد تم توجيه المبلغ المدخر نحو ترقية أنظمة التحكم في عربات النقل الآلية، مما يظهر مدى أهمية اختيار نوع الرافعات العلوية المناسبة لإدارة منشأة تحتاج إلى تدفق مستمر.

الممارسات المثلى في التخزين والتصنيع الخفيف

- مطابقة السعة : اختر الرافعات التي تم تصنيفها بنسبة 125٪ من أقصى حمولة تشغيلية لتجنب الإفراط في التحميل ومنع الإنفاق الزائد على المعدات ذات الأحجام الكبيرة

- التخطيطات القابلة للتعديل : قم بدمج الرافعات ذات العارضة الواحدة مع عوارض ممر قابلة للتعديل لتكيّفها مع تغيّرات المنتجات الموسمية (SKU) في مستودعات الخدمات اللوجستية الثالثية (3PL)

- الصيانة الوقائية : تقلل الفحوصات الفصلية لعجلات العربة وأحزمة الرافعة من توقف العمليات غير المخطط له بنسبة 41٪ في مرافق التعبئة (معهد المناولة 2024)

تُلغي الأنظمة ذات العارضة الواحدة ذات الأحجام المناسبة 87٪ من تكاليف الرافعات ذات العارضتين في التطبيقات التي تقل عن 15 طنًا، بينما تُحسّن المساحة الرأسية المُتاحة للتخزين بفضل هيكلها المدمج - وهو ما يفيد بشكل خاص المنشآت ذات الأسقف التي يقل ارتفاعها عن 24 قدمًا.

قسم الأسئلة الشائعة

- ما هي قدرة تحمل الرافعة ذات العارضة الواحدة؟ تشير قدرة التحميل إلى أقصى وزن يمكن للرافعة التعامل معه بشكل آمن. وتختلف هذه القدرة بناءً على المواد المستخدمة في صناعتها، وتصميم العوارض، والعوامل الهيكلية الأخرى.

- ما مدى تكرار فحص الرافعات ذات العارضة الواحدة؟ وفقًا لمواصفة CMAA 78، يجب إعادة شهادة صلاحية الرافعات كل أربع سنوات، إلى جانب إجراء فحوصات دورية للأجزاء الحرجة مثل حبال الأسلاك والتروس وعجلات العربة.

- متى يجب استخدام رافعة ذات عارضتين بدلاً من ذلك؟ الرافعات ذات العارضتين أكثر ملاءمة للمهام التي تتطلب سعة تحمل أعلى تزيد عن 20 طنًا أو فواصل أطول من 30 مترًا، خاصة في البيئات التي تتميز باستخدام يومي كثيف.

- ما هو هامش الأمان للرافعات ذات العارضة الواحدة؟ عادةً ما تكون لديها هامش أمان يعادل أربع مرات الحمل العامل لها، مما يعني أنها يجب أن تكون قادرة على تحمل إجهادات كبيرة دون أن تتعرض للتلف.

جدول المحتويات

- ما هي سعة تحمل الرافعة ذات العارضة المفردة ولماذا تهم

- العوامل الرئيسية التي تحدد قدرة تحمل الحمولة في الرافعات ذات العارضة الواحدة

- الرافعات ذات العارضة الواحدة مقابل الرافعات ذات العارضتين: سعة التحميل والمقايضات الهيكلية

- الامتثال والمعايير الخاصة بسعة التحميل في تصميم الرافعات العلوية

- التطبيقات الواقعية وتحسين استخدام سعة ونش العارضة الواحدة