Viktiga Hydrauliska Lyfttillbehör för Säkerhet och Effektivitet

Stabilisatorer och Stöd för Förbättrad Stabilitet

Stabilisatorer och stabilben gör all skillnad för säkerheten och att arbeta effektivt med hydrauliska lyft. Dessa lilla prylar hjälper till att förhindra att saker välter, vilket är anledningen till att de flesta operatörer vägrar använda en lyft utan att de först är monterade. När man arbetar med tunga laster innebär bra stabilisatorer att hela maskinen står stadigt istället för att guppa farligt. Stabilben gör något liknande men i större skala – de sprider ut basen på den utrustning vi använder, så att säga ger den extra ben. Utan korrekt uppställning händer olyckor alltför ofta på byggarbetsplatser världen över. Titta på OSHA:s rapporter eller tala med någon som regelbundet arbetar på arbetsplatsen, och de kommer att berätta vad som händer när någon hoppar över att korrekt använda dessa stabiliserande komponenter. Det kloka valet? Kontrollera alltid att både stabilisatorer och stabilben sitter fast på jämn mark innan arbetet påbörjas. Att göra detta rätt handlar inte bara om att följa regler – det räddar bokstavligen liv och förhindrar kostsamt skadegörelse i framtiden.

Säkerhetsräcken och fallskyddssystem

När man arbetar i höjd spelar säkerhetsräcken tillsammans med olika fallskyddssystem en avgörande roll för att hålla arbetstagare säkra. Dessa räcken fungerar i grunden som barriärer som hindrar personer från att falla oavsiktligt, och bildar något i stil med skyddande väggar runt de som arbetar på hydrauliska lyft. Det finns flera olika typer av fallskyddsutrustning tillgängliga idag, såsom kroppssele och dessa återfjädrande linor som låter arbetstagare röra sig fritt samtidigt som de förblir säkrade. Branschstatistik visar att fall från höga höjder fortfarande är en av de främsta orsakerna till skador på arbetsplatser. Genom att dock implementera lämpliga räckessystem tillsammans med adekvat fallskyddsutrustning kan dessa olyckor minska avsevärt. De flesta arbetsplatser måste följa regler som satts upp av organisationer som OSHA vad gäller krav på fallskydd. Dessa regler är inte bara byråkratisk röd tråd, utan de belyser faktiskt varför det är klokt med goda säkerhetsåtgärder både ur juridisk och praktisk synvinkel för alla företag som bryr sig om arbetstagarnas välbefinnande.

Nödföränklingssystem

Nödföränklingssystemet är en nödvändig säkerhetsfunktion för alla hydrauliska lyft, vilket gör att arbetare snabbt kan komma ner när något går fel. Utan detta system skulle personer som fastnar i hög höjd vara i stor fara om något skulle gå sönder eller en olycka inträffa. De flesta anläggningar använder antingen hydrauliska eller elektriska system för detta ändamål. Vi har sett många fall där dessa föränklingssystem bokstavligen räddat liv och förhindrat att situationer blivit ännu värre. Underhåll spelar också en stor roll. Bästa praxis är att kontrollera dessa system minst en gång per kvartal, kanske till och med varje månad beroende på hur mycket de används. Regelbundet servicearbete håller allt i gott skick så att ingen blir överraskad när snabb evakuering behövs. Därför prioriterar de flesta säkerhetsinspektorer nödföränklingssystem som toppfrågor vid sina rutinmässiga kontroller.

Kraft- och kontrollförbättringar för hydrauliska plattformar

Integration av eldriven kedjekrans

När eldrivna kedjekransar integreras med hydrauliska plattformar förbättrar de lyftkapaciteten avsevärt samtidigt som behovet av manuellt arbete minskar. Dessa kranar är byggda för att vara slitstarka och är ganska enkla att använda, vilket gör att de kan hantera tunga vikter exakt utan att trötta ut arbetarna lika mycket. De flesta tillverkare erbjuder idag elektriska modeller som faktiskt är kompatibla med olika typer av hydrauliska lyftare som finns på marknaden, så installationen har blivit mycket enklare. Några senaste studier visar på en produktivitetsökning om cirka 30 procent efter övergången till elektriska modeller, även om resultaten kan variera beroende på konfigurationen. Framöver förväntas det definitivt bli mer smart teknik integrerad i dessa enheter. Vi börjar redan se funktioner som avancerade styrsystem och fjärrövervakningsalternativ som standard. Denna typ av teknikutveckling förbättras hela tiden, och faktum är att den snabbt blir en nödvändighet för alla som idag använder moderna hydrauliska lyftutrustningar.

Fjärrstyrningssystem för precisionsdrift

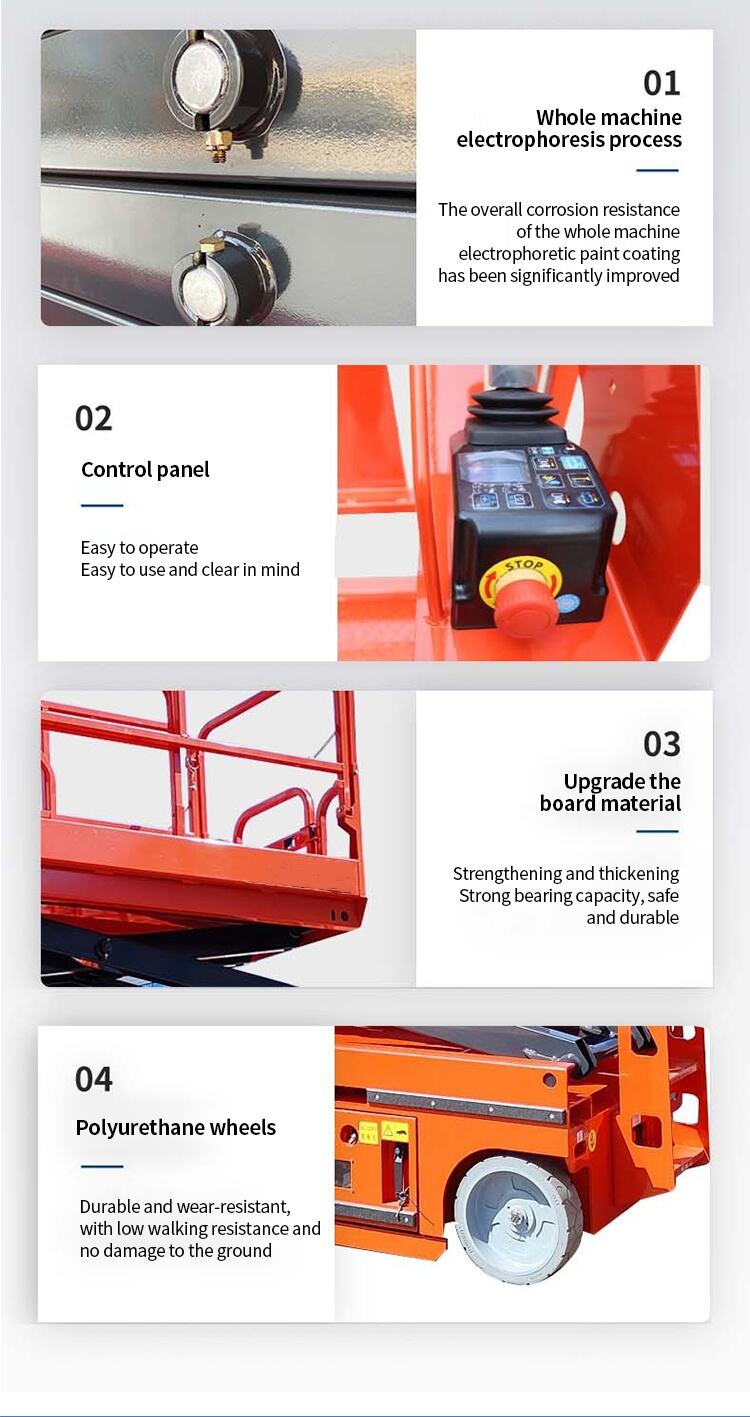

Hydrauliska lyftarbete fungerar mycket bättre när fjärrstyrningssystem används. Operatörer kan hantera dessa lyft från en säkrare plats borta från tunga maskiner, vilket minskar olyckor och säkerställer att allt fungerar som det ska. De flesta anläggningar har nu övergått till trådlösa fjärrkontroller eftersom de fungerar mycket bättre än de gamla trådbundna kontrollerna. Inga mer trassliga kablar som kommer i vägen eller begränsar var någon kan stå under drift. Fakta från verkligheten visar att arbetsplatser rapporterar färre olyckor sedan man började använda dessa fjärrsystem, vilket visar varför säkerhet fortsätter att vara en högsta prioritet inom branscherna. När du handlar efter ett fjärrstyrningssystem, tänk på hur lång räckvidd det har, hur länge batterierna håller mellan laddningar, och om knapparna känns bekväma i handen även efter timmar av användning. Moderna versioner innehåller ofta nödstoppfunktioner och justerbara inställningar som anpassas till specifika uppgifter. Dessa förbättringar är inte bara trevliga att ha – de blir snabbt standardutrustning eftersom företag prioriterar arbetssäkerhet tillsammans med ökad produktivitet.

Batteri Reserve Lösningar

Reservbatterier spelar en avgörande roll för att behålla hydrauliska lyftanordningar i drift när strömmen går ur. Utan dem står anläggningar inför stora problem till följd av oväntade driftstopp som stör arbetsflödet och orsakar kostsamma förseningar. Det finns flera batterityper att välja bland idag, bland annat litiumjon- och traditionella blysyra-batterier. De flesta operatörer föredrar litiumjonbatterier eftersom de är lättare och presterar bättre över tid, även om vissa fortfarande håller fast vid äldre teknik av budgetmässiga skäl. Branschrapporter visar att strömavbrott kostar företag miljoner varje år enbart i förlorad produktivitet, vilket är anledningen till att det är så viktigt att ha bra reservsystem. När dessa system installeras är det avgörande att välja rätt batteristorlek för arbetet och att allt fungerar tillsammans korrekt. Underhåll är också viktigt – regelbundna besiktningar och rätt lagringsförhållanden håller batterierna redo när de behövs allra mest, vilket ger anläggningscheferna trygghet även när stormar drabbar eller elnätet får fel.

Tillbehör för lagring och materialhantering

Hissdonkran tillbehör

Hissdonkran-tillbehör spelar en viktig roll i att flytta tunga laster noggrant och effektivt på industrilokaliteter. När de kombineras med hydrauliska lyftanordningar ser företag påtagliga förbättringar i sin dagliga materialhantering. Ta till exempel containerterminaler där dessa kombinationer verkligen märks, där de påskyndar godsflödet samtidigt som de minskar arbetskraftskostnaderna. Ett stort logistikföretag uppgraderade nyligen sin utrustning med dessa system och såg att arbetsflödet ökade med cirka 20 %. Innan några köp görs bör dock operatörerna kontrollera att tillbehöret kommer att fungera korrekt med deras befintliga hydrauliska lyftsystem, eftersom olika modeller har olika krav. Vissa tillbehör passar helt enkelt inte vissa lyftar, oavsett hur bra de ser ut på papperet.

Justerbara rörställningar och verktygsfack

Att lägga till justerbara rörställ och verktygsbrickor gör en stor skillnad när det gäller att organisera verktyg i industriella miljöer. Att hålla saker och ting i ordning runt arbetsområdet hjälper till att undvika olyckor och förbättrar de allmänna säkerhetsförhållandena. En aktuell branschrådgivningsrapport visade faktiskt att arbetsplatser hade cirka 15 procent färre incidenter efter att de börjat implementera bättre organisationslösningar. När det är mindre röra omkring, så tillbringar arbetare betydligt mindre tid på att jaga efter sin utrustning, vilket leder till att uppgifter slutförs snabbare under dagen. De flesta tillverkare erbjuder också många anpassningsalternativ för dessa lagringslösningar. De kan anpassas till olika typer av hydrauliska lyftoperationer utan besvärande ansträngning, vilket säkerställer att alla nödvändiga verktyg alltid finns där anställda behöver dem under sina arbetspass.

Modulära Plattformsförlängningar

Att lägga till modulära plattformar i hydraulsystem hjälper verkligen till att utöka arbetsområdena och ger arbetare mer utrymme att utföra sina uppgifter. Det som gör dessa förlängningar så användbara är hur anpassningsbara de är för alla slags projekt. Ta till exempel byggarbetsplatser, där extra plattformsutrymme innebär att arbetslag kan röra sig bättre utan att trängas, vilket minskar antalet olyckor. Att installera dem korrekt spelar också en stor roll. Arbetare måste noga följa säkerhetsprotokollen när de sätter ihop dessa konstruktioner och se till att allt klickar på ordentligt innan någon tung lyftning påbörjas. Att göra detta på rätt sätt ger två fördelar: ökad produktivitet och en säkrare arbetsplats överlag.

Specialiserade tillbehör för industriella applikationer

Lufttaljkompatibilitet för farliga miljöer

När man arbetar i farliga områden är det oöverträffat att använda luftvinscher istället för eldrivna modeller. Elektriska vinscher kan skapa gnistor som innebär allvarliga risker, medan luftvinscher drivs med tryckluft och inte antänder något i explosiva atmosfärer. Dessa pneumatiska enheter uppfyller de strikta säkerhetsreglerna som alla talar om (ATEX, IECEx) som gäller för platser där lättantändliga gaser förekommer. Ta olje- och gassektorn som exempel – att byta ut vanliga elvinscher till luftdrivna har förhindrat otaliga olyckor som annars kunde inträffa. Nackdelen? Luftvinscher kräver också ordentlig vård. Regelbundna kontroller av tryckluftsledningarna och att hålla smörjsystemet i gott skick är avgörande för långsiktig prestanda och säkerhet. Att utföra denna underhållsåtgärd korrekt gör att verksamheten förblir i enlighet med alla säkerhetsregler och spar pengar på sikt eftersom utrustningen håller längre.

Anpassningar av transportvinscher för tunga laster

Reselyftan är ganska imponerande maskiner som är byggda för att hantera riktigt tunga laster. De finns överallt på varv och båtplatser där de flyttar båtar och transporterar alla slags tunga utrustningar. Vad som gör dem så mångsidiga är att de är utrustade med justerbara spridarbalkar och flera hydraulvinschar som sprider ut vikten jämnt, vilket håller allt stabilt under lyftarbetena. Sjöfartsindustrin är kraftigt beroende av dessa maskiner, men byggarbetsplatser finner dem också oumbärliga när de ska hantera laster av olika storlekar. Säkerhet kommer alltid först. Operatörer måste genomgå grundlig utbildning innan de får köra maskinen. De måste veta hur man läser de komplicerade lastdiagrammen och vara redo att följa nödförfaranden om något skulle gå fel. Regelmässiga kontroller av utrustningen samt strikt efterlevnad av driftreglerna säkerställer att alla är trygga och att prestandan är hög överlag.

Integrering av lagerkranar för logistik

När lagerkranar kombineras med hydrauliska lyftar fungerar materialhanteringen helt enkelt bättre i alla avseenden. Hela operationen rör sig från sida till sida och upp och ner mycket effektivare, vilket innebär att lager kan utnyttja sitt begränsade golvutrymme bättre samtidigt som arbetet går snabbare. Logistikföretag har sett ganska imponerande resultat efter att ha satt upp sådana system. En stor distributör rapporterade exempelvis att man minskade manuell hantering med cirka 30 % och ökade den dagliga kapaciteten med nästan 25 %. Naturligtvis är det inte alltid enkelt att få allt att fungera tillsammans. Lagerchefer måste fundera över hur olika vikter påverkar balanspunkter och tidsproblem när flera maskiner arbetar samtidigt. De flesta anläggningar upptäcker att de behöver investera i avancerade styrelser som samordnar alla rörliga delar. Dessa system hjälper till att upprätthålla strikta säkerhetsprotokoll och samtidigt hålla arbetsflödena smidiga under hela arbetspassen.